Unconfigured Ad Widget

Collapse

|

|

|

|

|

|

|

|

Grizzly G4003G Gunsmith lathe

Collapse

X

-

Tags: None

-

That's nice! Every few months I go to Grizzly's site and try and work the numbers to afford one. Splitting it four ways is an incredibly smart way to go.

I'd love to see some of the projects you're using this for. Also, you mention building your own rifles. What types are you planning on? -

Very nice! Here is a pic of my 1940's Atlas 12x36. It was a project in itself but runs great now, I just got my hands on a quick change gear box for threading too! I will need to go through it first before installing it........

Comment

-

Looks great!

Only one word of warning. I read the advice of an experienced machinist who said to never put your tools on the "tray" on top of a lathe like that. If you are running at speed and they vibrate their way over the edge, they can turn into a projectile.Comment

-

One of the Grizzly gunsmith lathes is the next piece of equipment on my list.Comment

-

Dane and I ended up splitting it two ways because we really wanted it and had two comp guns that needed to be re-barreled. We got tired of dealing with shops and smiths. Here is some of what we have been doing with it.

7mm SAUM ELR rifle.

R+D RAD brake on my match rifle.

My match rifle (now sits in a McRee chassis)

Comment

-

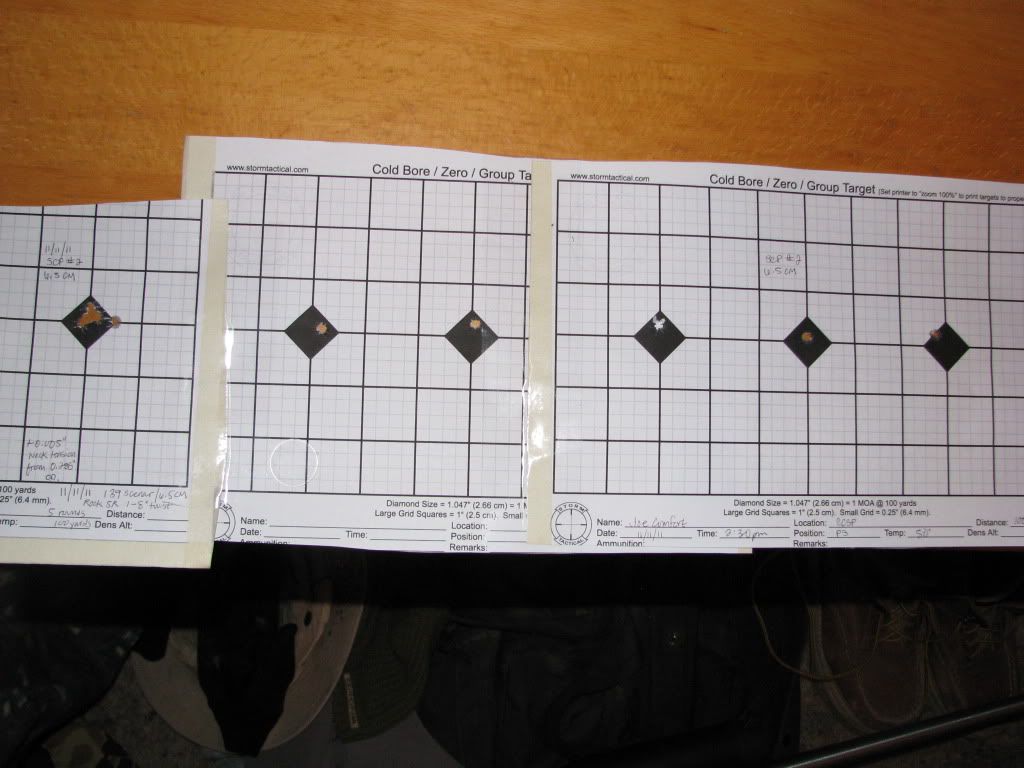

6.5 CM match rifle we built for a friend of ours.

Dane's match rifle (now in a McRee chassis)

We've also built a 6.5 CM match rifle for our team mate Beau and set back an existing barrel for a friend. We've done a good amount of threads for brakes, suppressors and chambering actions. We are still working on gathering the tooling for truing actions. My team mates and I have been working on standardizing our competition rifles. We will eventually all have the same load, dope, bore/scope axis, chassis and of course we all shot MOA/MOA scopes.Last edited by JFComfort; 11-26-2011, 6:18 PM.Comment

-

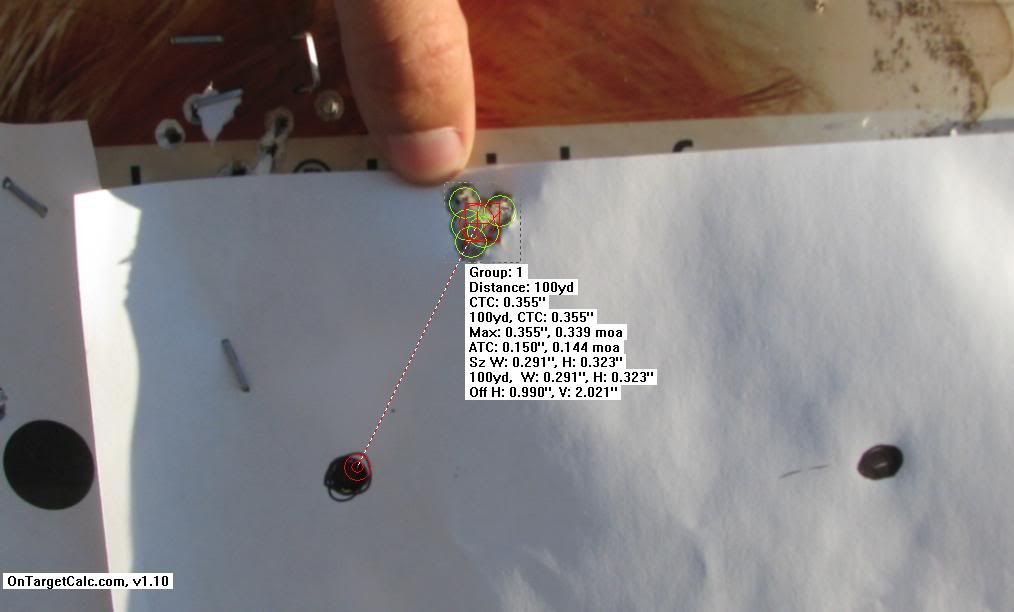

6.5 CM

7mm SAUM

We are very happy that all the rifles Dane and I have built shoot extremely well!Comment

-

This. Simply outstanding every step of the way.

Here's something from the other end of the rifle spectrum on my 4003G

On the threading, if you invert the cutting tool and run the lathe in reverse you'll be cutting away from the shoulder. You can run higher rpm and get cleaner cuts.

The speed issue can be solved with a VFD for ~$250. I have one on my mill but havn't added it to the lathe yet.

Who's barrel blanks are you using and which reamer holder is that?Last edited by ShaunBrady; 09-05-2022, 10:42 AM.Comment

-

Were using Rock Creek 5R's and I can't remember the make of the floating reamer holder. I'll get it next time I'm messing with the lathe or over at Dane's. We used a PTG piloted reamer. I'll have to check exactly which diam. bushing we used.Comment

-

-

Were using PTG range rods, and aligning the axis off the bore via range rod. I'm very interested in the Gordy's method. You can do many calibers with just 3 rods right?Comment

-

If you are doing precision rifle stuff and not going much bigger than .30 cal I think you probably only need two rods and the pilots that come with your reamers.

Oh and regardless of what their web site says, you need a #4 rod for .490 bores.

I haven't chambered anything yet (partially because PTG can't seem to send me pilots in the size I order) but I like the idea of aligning the chamber with the bore directly in front of the throat.

Once they send me the 0.4898 pilot I ordered, the first up is a .50 Beowulf for an RPK...Comment

-

Damn that is some awesome stuff.Comment

Calguns.net Statistics

Collapse

Topics: 1,850,481

Posts: 24,948,201

Members: 352,400

Active Members: 6,598

Welcome to our newest member, LoChapo.

What's Going On

Collapse

There are currently 1923 users online. 71 members and 1852 guests.

Most users ever online was 65,177 at 7:20 PM on 09-21-2024.

Comment