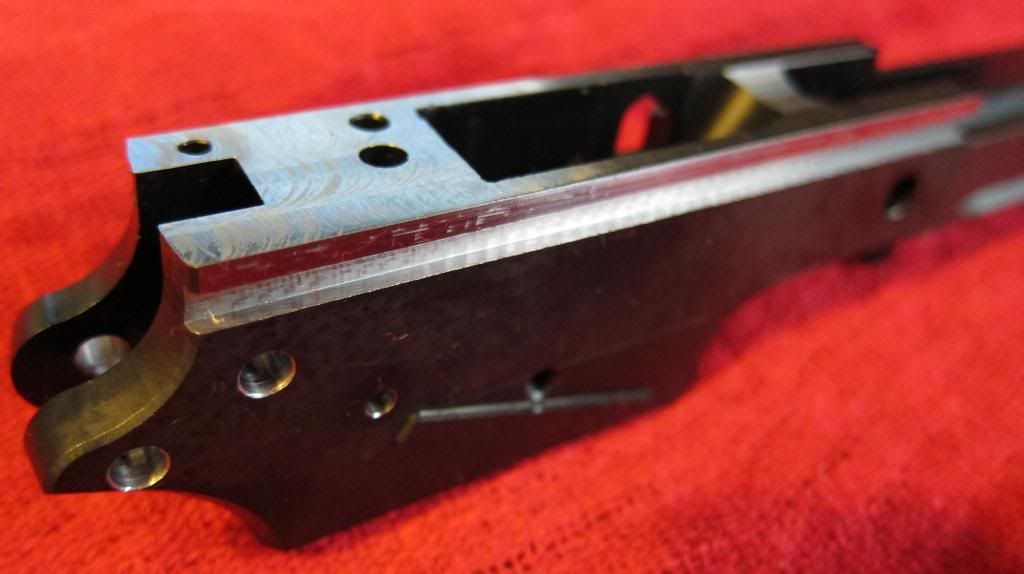

Looks like the only thing left to do is drill the ejector pin hole.

Unconfigured Ad Widget

Collapse

|

|

|

|

|

|

|

|

Ares Armor 1911 80% Build Experience

Collapse

X

-

-

Comment

-

Funny thing was there where a few ppl ahead of me and I took a peak at the finish product. I looked at them and also saw the same thing you are looking at within the pictures I posted.

I was up next and did 2 also, they both came out exactly the same as the pictures....Comment

-

Big cube sounds pretty sweet, say 6x6x6 with a setup on the top for the pin holes operations. Mill out the left and right sides on the bottom for clamps to hold to the table. Front could be for milling the rails/barrel bed/etc and setup the sides for other angle work.I wasn't thinking of something that versatile, more like a big aluminum ~cube with holes for mounting horizontal (for the pin holes) and vertical (for rails and barrel seat), with clearance cuts for rails, grip screw bushings and mag wells, dowel pins to locate everything and drill bushings so the aluminum won't wear out and a nice clamp to make sure the frame can not move while machining.

I don't think I will have to do any disconnector holes or frame ramps and I've got another jig in mind for doing front strap work.

I still have to machine the MSH slot in a KTO frame so I guess I should plan for that angle too. Maybe that angle for mag wells would be a good one.

The good thing about a cube is that it gives me four shots at vertical setups and I can cut slots to indicate by on the horizontal side and step clamp it to the table if the bolt holes don't line up.

I ordered Bull Hunters jig today, I'll let you know how it works out.Comment

-

Why?

They look ok to me.

The machining of the top of the rails looks fine, it's the only way to ensure the dimension from the top of the slot to the top of the rail is in spec.

If you indicate in the top surface, you won't need to make a cut on the top if your slot is cut at the right height but that's not very DIY friendly for CNC build parties.

That's the reason why I am planning to do all of mine manually, that will allow me to individually cut my frame to fit the intended slide.

Not everyone has the time or machine access to do that so the CNC build party is the next best option and far better than manual milling for a person that has never used a mill.Last edited by wash; 12-23-2012, 5:24 PM.Comment

-

Couch-After I saw your kto build thread I ordered a jig from bullhunter. I have been working on fitting all the small parts of my kto frame first. Everything needed to be fitted. The grip safety did not fit in the frame and took almost a day of filing and sanding to get it to fit. The mag release took about 4 hours to fit. Had to file the bumps/humps in the mag well. I am going to get started on the barrel seat, msh slots, and rails in the next couple weeks. Because the kto (and from the looks the ares also) have a wider dust cover area, the rest of the frame will need a shim under it to keep it square on the jig. I though about shimming one side and milling away the thicker area and then flip it and do the other side caiuse I don't like the rail on the kto frame anyway. I want to first cut the rails and such and test fire it before I put more time into messing with the dust cover. I may also cut off the extended mag well. I don't like it either.Comment

-

Thinking more about it, I'll probably get a piece of flat ground steel plate larger than the cube and bolt the cube to the plate from underneath with 82 degree fasteners.Big cube sounds pretty sweet, say 6x6x6 with a setup on the top for the pin holes operations. Mill out the left and right sides on the bottom for clamps to hold to the table. Front could be for milling the rails/barrel bed/etc and setup the sides for other angle work.

I ordered Bull Hunters jig today, I'll let you know how it works out.

I'll have bolt holes and pins to bolt it to the table square and the steel flange will be perfect for clamping.Comment

-

Figured I'd either be milling the fixture for rail clearance or shimming the frame away from the fixture to clear the rail.Couch-After I saw your kto build thread I ordered a jig from bullhunter. I have been working on fitting all the small parts of my kto frame first. Everything needed to be fitted. The grip safety did not fit in the frame and took almost a day of filing and sanding to get it to fit. The mag release took about 4 hours to fit. Had to file the bumps/humps in the mag well. I am going to get started on the barrel seat, msh slots, and rails in the next couple weeks. Because the kto (and from the looks the ares also) have a wider dust cover area, the rest of the frame will need a shim under it to keep it square on the jig. I though about shimming one side and milling away the thicker area and then flip it and do the other side caiuse I don't like the rail on the kto frame anyway. I want to first cut the rails and such and test fire it before I put more time into messing with the dust cover. I may also cut off the extended mag well. I don't like it either.

I'm glad a lot of it is oversize, much rather have that than undersize and leave gaps. That and I'm building it with mainly EGW parts which come oversize in just the right areas, it should all pretty much look like one single piece when finished!Comment

-

Could go that route, but flipping the cube on its side and milling a few slots you could omit the base plate all together. Steel would obviously last longer than aluminum but really not that necessary with a cube that size.Thinking more about it, I'll probably get a piece of flat ground steel plate larger than the cube and bolt the cube to the plate from underneath with 82 degree fasteners.

I'll have bolt holes and pins to bolt it to the table square and the steel flange will be perfect for clamping.

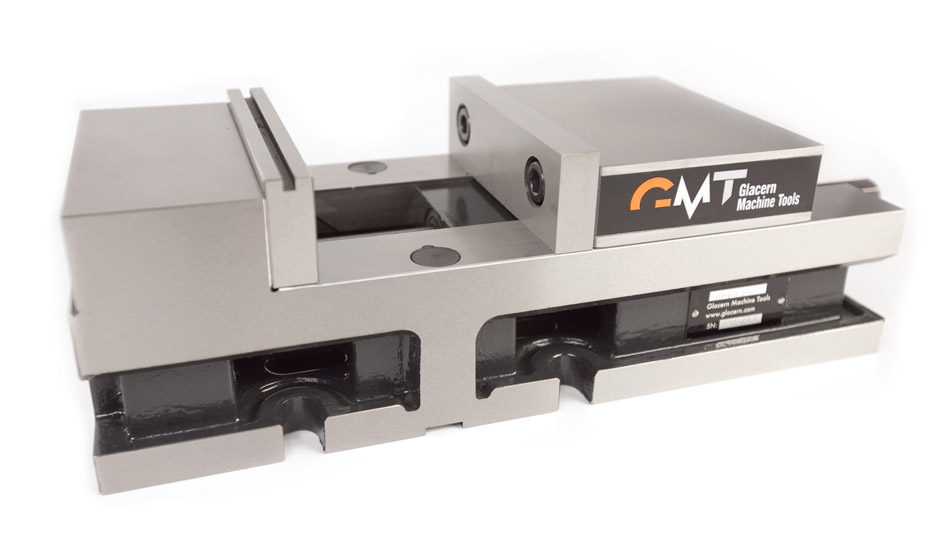

Slots similar to some machine vices...

Comment

Calguns.net Statistics

Collapse

Topics: 1,855,693

Posts: 25,010,610

Members: 353,847

Active Members: 5,714

Welcome to our newest member, Hadesloridan.

What's Going On

Collapse

There are currently 3584 users online. 152 members and 3432 guests.

Most users ever online was 65,177 at 7:20 PM on 09-21-2024.

Comment