My project to fill in a thumbhole stock is finally finished. The first one done is an AK stock. Here's how I did it.

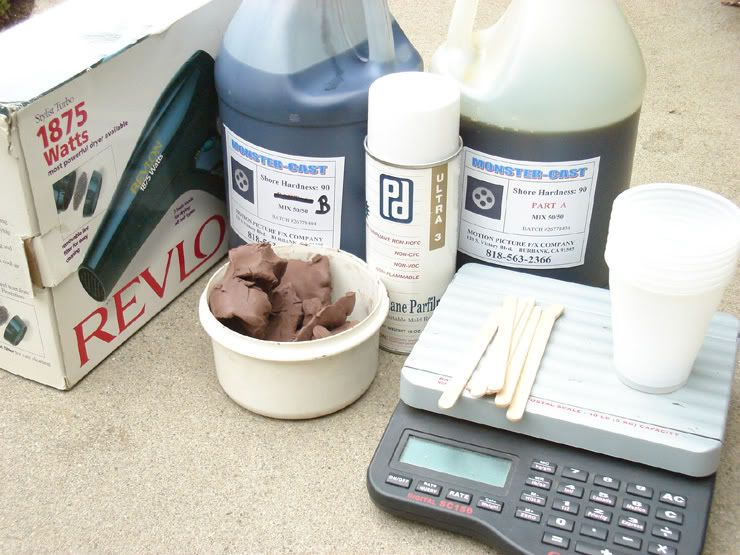

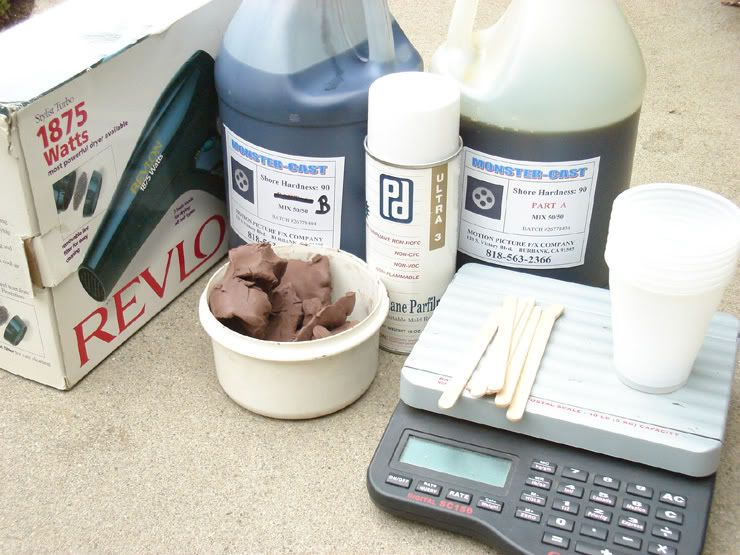

First the supplies.

I bought a one gallon kit of polyurethane mix, called "Monster Cast". It'll make 2 gallons actually. I opted for the black mix, so I didn't have to add anything to it to get it to that color. Here's where I purchased it from:

MOTION PICTURE F/X COMPANY

123 S. VICTORY BLVD.

BURBANK, CA 91502

818 563-2366

I had to also buy a urethane parfilm spraycan to coat whatever I'm pouring the mix onto, so that it does not bond with the surface, and some molding clay as well. To use it, you measure out equal amounts of each liquid, then stir them together vigoriously for 30 seconds, pour them into the stock and they will combine to become a solid. Here is everything you need, including the mix and parfilm, a scale, stir sticks, clay, plastic cups, and a hair dryer (used to soften the clay). CAUTION: This material is an irritant. Do not inhale it, get it on your skin, or work with it in an enclosed space. Take the neccessary precautions.

Preparing the stock.

It's a two piece design. I started with the molding clay and filled in 2/3rds of the stock to make the first piece, a small filler to be used as a plug so that I could pour the mix directly into the stock. Pack the clay from the left side as flat as possible, and spray the parfilm so that the piece can easily come out, then pour.Here's the finished part.

I then screwed the stock screw back into the top of the stock and plugged the bottom of the hole with a little clay. Next I used a drill bit and dremel cutter to cut a hole into it and countersink a black wood screw just long enough to be completely covered by the polyurethane mix. I also cut and countersunk two additional wood screws near the end of the buttstock. (Tip: when cutting into the wood with the dremel, apply oil to it to keep the burning to a minimum)Then the small piece is secured to the stock with tape and more clay is molded around the sling attachment to create a dam to hold the mix. Like this.

Pouring the mix. CAUTION: This material is an irritant. Do not inhale it, get it on your skin, or work with it in an enclosed space.

I decided to pour the liquid in two parts, so addtional screws were inserted into the stock to hold both parts together just in case they did not bond to each other. Next I spray the parfilm onto the surface where I'm going to pour the mixture. I poured the first batch and waited for it to harden but not completely set so that it has a better chance of bonding with the second coat. Then I poured the second batch, being watchful of the rising level of the mix. Once done I let it set and remove the clay. The finished product is a very solid filler attached to the stock in three places to make it secure. And there you have it. A non-thumbhole (nunhole) stock. I have plenty of polyurethene left to do additional AK thumbhole stocks and will also try and do an HK91 stock.

Click on the photo to view the video.

First the supplies.

I bought a one gallon kit of polyurethane mix, called "Monster Cast". It'll make 2 gallons actually. I opted for the black mix, so I didn't have to add anything to it to get it to that color. Here's where I purchased it from:

MOTION PICTURE F/X COMPANY

123 S. VICTORY BLVD.

BURBANK, CA 91502

818 563-2366

I had to also buy a urethane parfilm spraycan to coat whatever I'm pouring the mix onto, so that it does not bond with the surface, and some molding clay as well. To use it, you measure out equal amounts of each liquid, then stir them together vigoriously for 30 seconds, pour them into the stock and they will combine to become a solid. Here is everything you need, including the mix and parfilm, a scale, stir sticks, clay, plastic cups, and a hair dryer (used to soften the clay). CAUTION: This material is an irritant. Do not inhale it, get it on your skin, or work with it in an enclosed space. Take the neccessary precautions.

Preparing the stock.

It's a two piece design. I started with the molding clay and filled in 2/3rds of the stock to make the first piece, a small filler to be used as a plug so that I could pour the mix directly into the stock. Pack the clay from the left side as flat as possible, and spray the parfilm so that the piece can easily come out, then pour.Here's the finished part.

I then screwed the stock screw back into the top of the stock and plugged the bottom of the hole with a little clay. Next I used a drill bit and dremel cutter to cut a hole into it and countersink a black wood screw just long enough to be completely covered by the polyurethane mix. I also cut and countersunk two additional wood screws near the end of the buttstock. (Tip: when cutting into the wood with the dremel, apply oil to it to keep the burning to a minimum)Then the small piece is secured to the stock with tape and more clay is molded around the sling attachment to create a dam to hold the mix. Like this.

Pouring the mix. CAUTION: This material is an irritant. Do not inhale it, get it on your skin, or work with it in an enclosed space.

I decided to pour the liquid in two parts, so addtional screws were inserted into the stock to hold both parts together just in case they did not bond to each other. Next I spray the parfilm onto the surface where I'm going to pour the mixture. I poured the first batch and waited for it to harden but not completely set so that it has a better chance of bonding with the second coat. Then I poured the second batch, being watchful of the rising level of the mix. Once done I let it set and remove the clay. The finished product is a very solid filler attached to the stock in three places to make it secure. And there you have it. A non-thumbhole (nunhole) stock. I have plenty of polyurethene left to do additional AK thumbhole stocks and will also try and do an HK91 stock.

Click on the photo to view the video.

Comment