Got done with this build, sanded and polished the crap out of the rails, made sure I removed all necessary material and probably a little extra, took it out for its maiden voyage.... and it's single shot. lol

The slide doesn't even recoil enough to eject the round 98% of the time (it has ejected the round once out of about 50 attempted rounds so far).

I'm at a loss as to what the problem is. Spring rate? I don't know. There does seem to be a little friction still, but not enough where I'd think it has the chance to stop the recoil an inch into it's travel.

Here's a list of the relevant parts:

Lone Wolf Enhanced Trigger Parts Kit

Shadow Systems Slide Kit & Recoil Spring Assembly

L2D Slide

True Precision Barrel

Tried three different magazine, happened with every one.

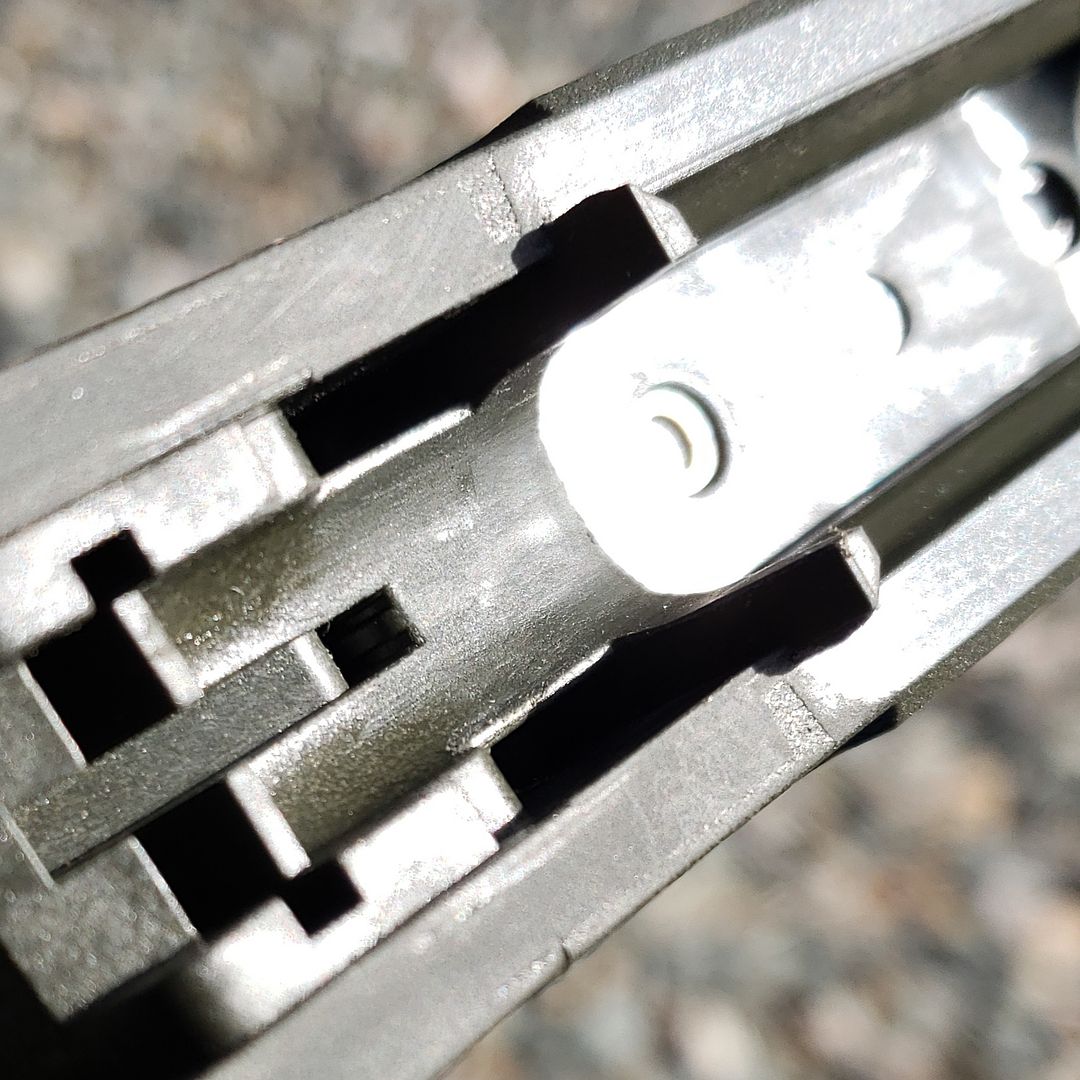

A picture of about how far the slide gets every time is attached.

Anyone have any advice on what I should try? My next thought would be to start replacing the internals with standard Glock parts, but I'm not so sure that'd do the trick?

TIA

The slide doesn't even recoil enough to eject the round 98% of the time (it has ejected the round once out of about 50 attempted rounds so far).

I'm at a loss as to what the problem is. Spring rate? I don't know. There does seem to be a little friction still, but not enough where I'd think it has the chance to stop the recoil an inch into it's travel.

Here's a list of the relevant parts:

Lone Wolf Enhanced Trigger Parts Kit

Shadow Systems Slide Kit & Recoil Spring Assembly

L2D Slide

True Precision Barrel

Tried three different magazine, happened with every one.

A picture of about how far the slide gets every time is attached.

Anyone have any advice on what I should try? My next thought would be to start replacing the internals with standard Glock parts, but I'm not so sure that'd do the trick?

TIA

Comment