I'm having issues FL sizing 308 brass. This is my first batch of 308 I'm reloading so maybe I'm doing something wrong. I'm using custom grade Hornady die installed per Hornady specs (put in until die touches shell holder).Hornady one shot lube, on a single stage RCBS press. I set up the cases in a tray and sprayed them with one shot at an angle to get some in the case mouth and all sides. I waited about a minute per Hornady instructions before sizing. The first case was real hard to get all the way into the die, I used a lot of force. Getting it out was a little easier. The second case I couldn't get all the way into the die and the 3rd case took a lot of force to get into die and ripped the case head off when trying to get out. Once I get this stuck case out I'm going to give it another try, any advice would be greatly appreciated.

Unconfigured Ad Widget

Collapse

|

|

|

|

|

|

|

|

Hard sizing 308

Collapse

X

-

Hard sizing 308

Tags: None -

Hard sizing 308

If your doing a full length sizing of the brass. Clean up, dry all new dies and make sure to lite lube inside the case mouth.

Last edited by Flyron; 02-21-2024, 6:05 PM.Comment

-

Yes, cleaned everything before I started.Comment

-

This set of brass was bought at OC reloadingComment

-

Try a different lube. One shot, if used properly will work, but a lot of people don't read the instructions, don't use enough and let the solvent flash off before using.

If you have some synthetic motor oil in the house, try a few cases with a light coat and see if they will size.Comment

-

Never had an issue using this spray lube in the last 10 years....

Comment

-

Save the one-shot lube for pistol brass.I'm having issues FL sizing 308 brass. This is my first batch of 308 I'm reloading so maybe I'm doing something wrong. I'm using custom grade Hornady die installed per Hornady specs (put in until die touches shell holder).Hornady one shot lube, on a single stage RCBS press. I set up the cases in a tray and sprayed them with one shot at an angle to get some in the case mouth and all sides. I waited about a minute per Hornady instructions before sizing. The first case was real hard to get all the way into the die, I used a lot of force. Getting it out was a little easier. The second case I couldn't get all the way into the die and the 3rd case took a lot of force to get into die and ripped the case head off when trying to get out. Once I get this stuck case out I'm going to give it another try, any advice would be greatly appreciated.

Get some Imperial sizing wax or make up some Lanolin/Alcohol lube for resizing rifle brass.

I can get that stuck case out if you don't figure it out on your own.Randall Rausch

AR work: www.ar15barrels.com

Bolt actions: www.700barrels.com

Foreign Semi Autos: www.akbarrels.com

Barrel, sight and trigger work on most pistols and shotguns.

Most work performed while-you-wait.Comment

-

Yeah; don't do that. Invariably, those instructions will oversize the brass to the point where a couple more firings will yield separated cases (potentially dangerous - Google "incipient case head separation" or variants thereof for more info.)

Take a couple of fired 308 cases, and either reseat or remove the primer (it will back out when fired, and will interfere with measurements.) If you have no other Case-Base-to-Datum measurement tools (i.e. Hornady Headspace tool), take an empty 9mm case and invert it over the 308 case mouth. Measure the 308 head to 9mm head length. Write that number down. Run the 308 case through your sizing die, and remeasure. You're aiming for 1-3 thousandths shorter after sizing for a bolt rifle, 2-5 thousandths for a semi-auto rifle. Adjust the die and resize until you get there. If the stroke ends up taking a lot of effort, I find that going in small increments, shoving the case in a bit and backing it out, then going a bit further, helps to not jam the case in the die.

For the effort, try waiting longer with One-Shot. Spray it on (don't drench it - just an even coating - I lay cases out, spray, roll the cases, and spray again) and let them air dry for 15 minutes. Make sure you get some inside the case mouths - it'll ease the expander ball part of the sizing process. If you spray One-Shot into the sizing die (I think Hornady recommended that, if not them, I've seen it suggested by someone) make sure you allow it to dry there, too, before sizing brass.

One-Shot doesn't like playing with other lubes. As stated above, make sure the die has been cleaned of other oils/greases/waxes/lubes.

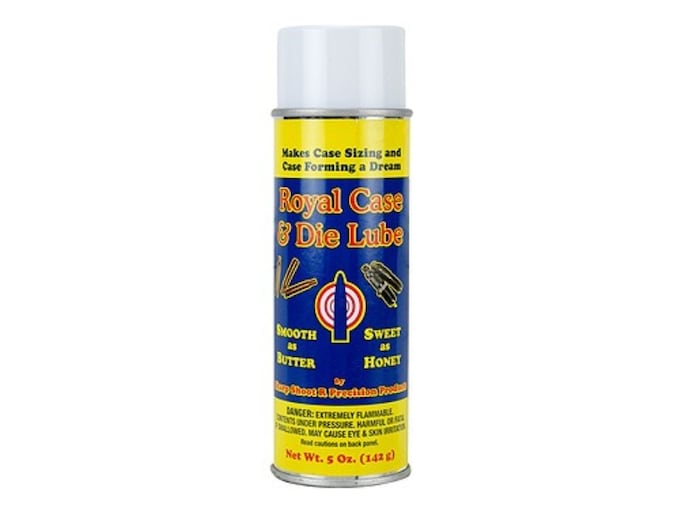

Lastly, there are a lot of other case lubes that are less finicky than One Shot. They do tend to be a little messier though. I use the Royal that someone suggested when I do large loads of brass. Smaller batches I use One Shot. For precision rifle brass I use Imperial or Hornady wax (small batches on a single stage or arbor press.)

it's all about getting a system down that works for you.Comment

-

It has to be a lube problem, I'm thinking.

I use the Lanolin/alcohol mix with no issues, and I size military brass on a SB die.

Stuck case removal is easy, and thre are several instructional videos on YouTube.Always looking for vintage Winchester and Marlin lever action rifles. Looking to sell? Know of one for sale? Drop me a line!

"Give a conservative a pile of bricks and you get a beautiful city. Give a leftist a city and you get a pile of bricks."Comment

-

It has to be a lube problem, I'm thinking.

I use the Lanolin/alcohol mix with no issues, and I size military brass on a SB die.

Stuck case removal is easy, and thre are several instructional videos on YouTube.Always looking for vintage Winchester and Marlin lever action rifles. Looking to sell? Know of one for sale? Drop me a line!

"Give a conservative a pile of bricks and you get a beautiful city. Give a leftist a city and you get a pile of bricks."Comment

Calguns.net Statistics

Collapse

Topics: 1,855,056

Posts: 25,002,112

Members: 353,847

Active Members: 6,014

Welcome to our newest member, RhythmInTheMeat.

What's Going On

Collapse

There are currently 2677 users online. 40 members and 2637 guests.

Most users ever online was 65,177 at 7:20 PM on 09-21-2024.

Comment