I reload 223 and 9mm by the bucket.

I am mostly shooting steel plates and cardboard in action type matches.

I don't bother to do match prep of the brass for ammo like this because it won't make enough difference.

I don't deburr flash holes, clean primer pockets, uniform primer pockets, turn case necks or weigh cases/bullets.

Consider the techniques and methods below to be for general purpose ammo, not match grade ammo.

All brass needs to get cleaned and sized before you can reload it.

I am going to describe my rifle brass process because it is much more involved.

Pistol brass skips the whole operation where the brass gets sized and trimmed as I size the pistol ammo on the same press that loads it.

The bucket method

I don't like to individually handle brass.

I use what I like to call the "bucket method".

I pickup dirty brass off the ground and it goes in a bucket.

I sort the brass by cartridge to ensure that only one cartridge type (223/9mm etc...) is in each bucket.

Pour the bucket in the tumbler to clean it.

Seperate the brass from the media.

Pour clean brass in the casefeeder on the sizing/trimming machine.

My press lubes, decaps, sizes and trims all in one setup.

Pour the sized/lubed/trimmed brass in the tumbler again to remove lube.

Seperate the brass from the media.

Pour fully processed brass in the casefeeder of the loading machine.

The loading machine clears the flash hole of media, swages the primer pocket, primes, charges, seats and crimps.

Out comes finished ammo.

Case Inspection

Some people may point out that I am not inspecting the cases.

The inspection for damaged cases happens during the lube/size/trim as you get to feel when you have a hard-to-size case and cull these to the scrap bucket.

It's better to catch them early than wait until they are in the press being loaded.

Trimming

You have to trim rifle cases before you can reload them unless you know that the length of each case is acceptable.

I load in large quantities so it's actually faster for me to trim the cases than to check the length.

There are besically two methods to trim cases in large quantities, a Dillon Trimmer or a Giraud Trimmer.

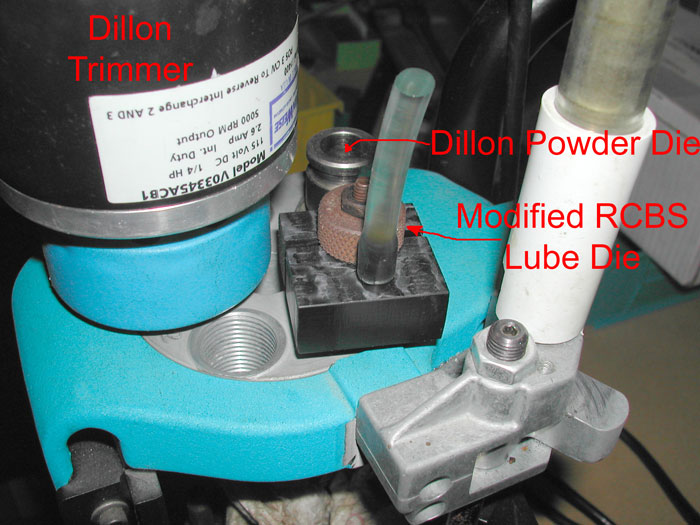

The Dillon trimmer is basically a full length sizing die with a motorized carbide cutter on top.

The case gets pushed up into the trim die and a portion of the neck sticks out the top of the die.

The trim length is set by adjusting the cutter height until it trims the case to the desired length.

You size and trim in one pass.

The Dillon trimmer does NOT lube, decap, neck expand or chamfer/deburr the cases though.

The Dillon trimmer's big advantage comes when you use it on a progressive press.

You can add other dies on the toolhead to deprime, lube, and neck expand.

That lets you deprime, size, trim and neck expand all at the same time.

The Giraud trimmer operates much like an electric pencil sharpener.

You insert the case into the trimmer, press it inward and rotate 1/2 turn.

The neck sticks into the trimmer body.

There is a rotating carbide cutter inside the trimmer body that cuts off the excess length.

The cutter is setup in such a manner that it also deburrs the outside and chamfers the inside of the neck.

The Giraud does NOT lube, deprime, size or neck expand the case.

You would have to do that in regular dies which does add several operations if you are loading on a single stage press.

This could all be done in a progressive press though and then you would only need to do the actual trimming on the Giraud.

While the Giraud is nice and fast and I use one for match prepped brass, the dillon is much faster when you include the time to size the cases.

Also, your fingers won't be sore as you don't have to actually handle each case.

It's my opinion that a Dillon trimmer setup on a progressive press with a casefeeder is the better method to process brass by the bucket because you can do everything in a single pass through the press without having to handle individual cases.

If you are not processing brass in bulk, then a Giraud is probably a better setup, especially if you don't use a progressive press.

Trim length accuracy

The primary reasons for trimming are two-fold.

First, you don't want the case to be so long that it could jam into the end of the chamber's neck and elevate pressures.

This has a relatively low tolerance requirement.

The case just needs to be short enough to NOT hit the end of the chamber's neck.

Second, you want the trim length consistent in order to apply a consistent crimp.

This has a much higher tolerance requirement as a consistent crimp is important to consistent ignition and resultant accuracy.

There's two ways to look at trim length accuracy.

One way is to measure the neck length from the headspace datum to the end of the case.

The other way is to measure the length of the case with a pair of calipers.

I believe the second method is better because it ensures a more consistent crimp.

Girard's trim length consistency relies on the shoulder length being consistent in order for trim lengths to be consistent.

The Dillon trim lengths reference to the case head, regardless of shoulder length consistency, so press frame stretch during sizing is the only variable.

So, let's assume that cases will be sized, but due to differences in brass hardness or annealing, that the headspace lengths will all be within 0.003" or so throughout a run of cases.

This is about what I have found when measuring a bunch of cases of all different headstamps run through the same sizing setup.

If you trim these cases referenced from the shoulder and make an assumption that the case trimmer will trim to 0.001" repeatedly, you SHOULD find that the OAL is all within 0.002" to 0.004" when measured to the case head.

Now, look at the design of a reloading press and you will note that the datum point is the case head.

When you are shoving the case into the sizing die, the case head is pushed against.

When you are shoving the case into the seating die, the case head is pushed against.

When you are shoving the case into the crimping die, the case head is pushed against.

The distance from the feature of the die that causes the crimp is only held consistent to the press ram (shellholder/case head), NOT to the case's shoulder.

So, in order for crimps to be consistent, you need the OVERALL CASE LENGTH to be consistent, NOT the neck length from the shoulder.

Now look at a trimming solution like the Dillon that I use.

The trim lengths will generally be between 0.001" to 0.002" throughout the whole run of brass.

The shoulder's length is NOT a factor.

With the more consistent trim length, you will get more consistent crimps.

Of course, if you are not crimping, it will NOT matter what datum is used to determine trim length.

You are only working in the low tolerance requirements of just being sure that your cases are not too long.

In the end, either trimming method is probably fine.

Match grade ammo using match grade bullets are usually not crimped.

I am mostly shooting steel plates and cardboard in action type matches.

I don't bother to do match prep of the brass for ammo like this because it won't make enough difference.

I don't deburr flash holes, clean primer pockets, uniform primer pockets, turn case necks or weigh cases/bullets.

Consider the techniques and methods below to be for general purpose ammo, not match grade ammo.

All brass needs to get cleaned and sized before you can reload it.

I am going to describe my rifle brass process because it is much more involved.

Pistol brass skips the whole operation where the brass gets sized and trimmed as I size the pistol ammo on the same press that loads it.

The bucket method

I don't like to individually handle brass.

I use what I like to call the "bucket method".

I pickup dirty brass off the ground and it goes in a bucket.

I sort the brass by cartridge to ensure that only one cartridge type (223/9mm etc...) is in each bucket.

Pour the bucket in the tumbler to clean it.

Seperate the brass from the media.

Pour clean brass in the casefeeder on the sizing/trimming machine.

My press lubes, decaps, sizes and trims all in one setup.

Pour the sized/lubed/trimmed brass in the tumbler again to remove lube.

Seperate the brass from the media.

Pour fully processed brass in the casefeeder of the loading machine.

The loading machine clears the flash hole of media, swages the primer pocket, primes, charges, seats and crimps.

Out comes finished ammo.

Case Inspection

Some people may point out that I am not inspecting the cases.

The inspection for damaged cases happens during the lube/size/trim as you get to feel when you have a hard-to-size case and cull these to the scrap bucket.

It's better to catch them early than wait until they are in the press being loaded.

Trimming

You have to trim rifle cases before you can reload them unless you know that the length of each case is acceptable.

I load in large quantities so it's actually faster for me to trim the cases than to check the length.

There are besically two methods to trim cases in large quantities, a Dillon Trimmer or a Giraud Trimmer.

The Dillon trimmer is basically a full length sizing die with a motorized carbide cutter on top.

The case gets pushed up into the trim die and a portion of the neck sticks out the top of the die.

The trim length is set by adjusting the cutter height until it trims the case to the desired length.

You size and trim in one pass.

The Dillon trimmer does NOT lube, decap, neck expand or chamfer/deburr the cases though.

The Dillon trimmer's big advantage comes when you use it on a progressive press.

You can add other dies on the toolhead to deprime, lube, and neck expand.

That lets you deprime, size, trim and neck expand all at the same time.

The Giraud trimmer operates much like an electric pencil sharpener.

You insert the case into the trimmer, press it inward and rotate 1/2 turn.

The neck sticks into the trimmer body.

There is a rotating carbide cutter inside the trimmer body that cuts off the excess length.

The cutter is setup in such a manner that it also deburrs the outside and chamfers the inside of the neck.

The Giraud does NOT lube, deprime, size or neck expand the case.

You would have to do that in regular dies which does add several operations if you are loading on a single stage press.

This could all be done in a progressive press though and then you would only need to do the actual trimming on the Giraud.

While the Giraud is nice and fast and I use one for match prepped brass, the dillon is much faster when you include the time to size the cases.

Also, your fingers won't be sore as you don't have to actually handle each case.

It's my opinion that a Dillon trimmer setup on a progressive press with a casefeeder is the better method to process brass by the bucket because you can do everything in a single pass through the press without having to handle individual cases.

If you are not processing brass in bulk, then a Giraud is probably a better setup, especially if you don't use a progressive press.

Trim length accuracy

The primary reasons for trimming are two-fold.

First, you don't want the case to be so long that it could jam into the end of the chamber's neck and elevate pressures.

This has a relatively low tolerance requirement.

The case just needs to be short enough to NOT hit the end of the chamber's neck.

Second, you want the trim length consistent in order to apply a consistent crimp.

This has a much higher tolerance requirement as a consistent crimp is important to consistent ignition and resultant accuracy.

There's two ways to look at trim length accuracy.

One way is to measure the neck length from the headspace datum to the end of the case.

The other way is to measure the length of the case with a pair of calipers.

I believe the second method is better because it ensures a more consistent crimp.

Girard's trim length consistency relies on the shoulder length being consistent in order for trim lengths to be consistent.

The Dillon trim lengths reference to the case head, regardless of shoulder length consistency, so press frame stretch during sizing is the only variable.

So, let's assume that cases will be sized, but due to differences in brass hardness or annealing, that the headspace lengths will all be within 0.003" or so throughout a run of cases.

This is about what I have found when measuring a bunch of cases of all different headstamps run through the same sizing setup.

If you trim these cases referenced from the shoulder and make an assumption that the case trimmer will trim to 0.001" repeatedly, you SHOULD find that the OAL is all within 0.002" to 0.004" when measured to the case head.

Now, look at the design of a reloading press and you will note that the datum point is the case head.

When you are shoving the case into the sizing die, the case head is pushed against.

When you are shoving the case into the seating die, the case head is pushed against.

When you are shoving the case into the crimping die, the case head is pushed against.

The distance from the feature of the die that causes the crimp is only held consistent to the press ram (shellholder/case head), NOT to the case's shoulder.

So, in order for crimps to be consistent, you need the OVERALL CASE LENGTH to be consistent, NOT the neck length from the shoulder.

Now look at a trimming solution like the Dillon that I use.

The trim lengths will generally be between 0.001" to 0.002" throughout the whole run of brass.

The shoulder's length is NOT a factor.

With the more consistent trim length, you will get more consistent crimps.

Of course, if you are not crimping, it will NOT matter what datum is used to determine trim length.

You are only working in the low tolerance requirements of just being sure that your cases are not too long.

In the end, either trimming method is probably fine.

Match grade ammo using match grade bullets are usually not crimped.

Comment