I've been looking through the range pickup brass I have, and I know a good bunch of it has been reloaded. The bulk is Lake City 5.56 as well as other 5.56 that has had the crimps removed. Plus the range I go to only sells their reloads.

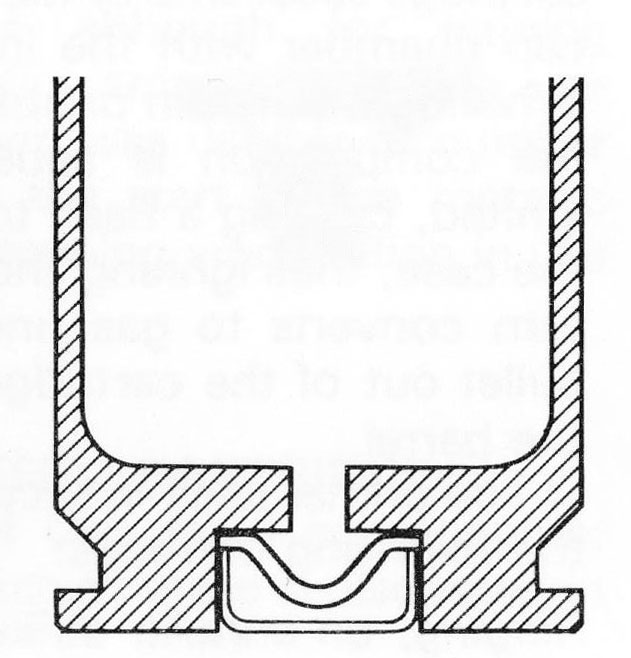

Now I resized about 100 of them, and so far 75% of them have that discolouration/ring right where the case separation would be. I stuck a paper clip in a couple of cases and didn't notice any groove or divet. I'm wondering if I'm just being paranoid, or if my resizing die is stressing the brass? I have a lee single stage with their full length resizing die. I set it up according to the manual and everything seems to be okay.

Can some more experienced reloaders tell me if I should toss this brass?

Thanks.

Now I resized about 100 of them, and so far 75% of them have that discolouration/ring right where the case separation would be. I stuck a paper clip in a couple of cases and didn't notice any groove or divet. I'm wondering if I'm just being paranoid, or if my resizing die is stressing the brass? I have a lee single stage with their full length resizing die. I set it up according to the manual and everything seems to be okay.

Can some more experienced reloaders tell me if I should toss this brass?

Thanks.

Comment