+

+  +

+  +

+  +

+  =

=

~270 .357 brass, ~500 .38 Special brass.

Bullets are B4rry's Lead Flat Point (FP) (truncated cone), 125gr (a standard / middlin' weight for this caliber.

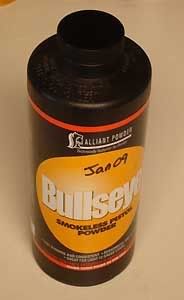

I used 8 grains of Bullseye in the .357 loads, and 4.8gr for the .38 Special.

All told it took me just about 3hrs to crank out just under 800rds. That includes resetting the powder and bullet seating dies on the press as well as the powder charge. Includes fiddling with all 800 rounds to wipe off surplus bullet lube and a few lead shavings (didn't quite set the powder funnel height low enough on the .38 Special, so the case mouths weren't being flared open quite enough. I got it done well enough, but should have made the adjustment, instead of having to deal with the after effects.

Also includes a halt to repair a busted primer cup stem(?) on the press' priming system, thankfully I had one in the Press common spares kit which I bought for just such occasions.

-

Material cost about 12.5 cents per round, averaged. $6.25/50. About 40% the cost of the cheapest non-reloadable plinking ammo.

Most of my equipment I've had for nearly 20yrs. It's cost has been amortized to nothing by now. Total outlay on reloading equipment has been about ~~$850, and/but my kit is pretty low-tech. The press itself is the fanciest piece of gear I've got. And a nice Dillon SuperSwage for opening up military crimps on brass. Still using the basic balance scale I started out with. No trimmer equipment. A single powder funnel setup on the press. 5 interchangeable toolheads and 9 calibers of dies. I usually load in large batches like this, so the issues of swapping out dies, powder funnel and the normal routine of swapping out large primer systems and powder transfer bars for their smaller counterparts on the press itself really isn't an inconvenience.

When I got this huge *** box from Dillon, I was like WTF is this?

When I got this huge *** box from Dillon, I was like WTF is this? And then she told me that she had ordered them for me so that I could put all my reloaded rounds in them. I really did not want them boxes because I prefer the plastic green ones from Cabelas but I did not want to tell her that I did not want them so I kept them.

And then she told me that she had ordered them for me so that I could put all my reloaded rounds in them. I really did not want them boxes because I prefer the plastic green ones from Cabelas but I did not want to tell her that I did not want them so I kept them.

Comment