Yes, I know I will probably get 5 different opinions from 4 different people. Anyways...

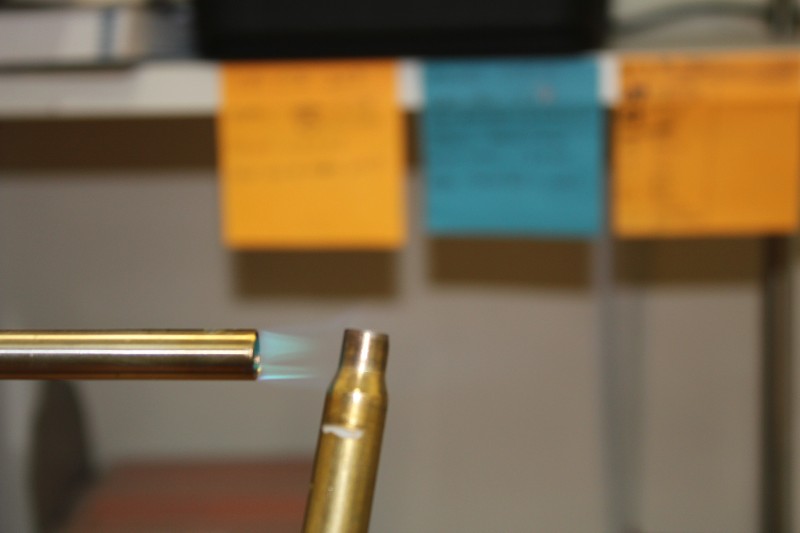

Having never read Tempilaq before, I can't quite tell if I'm getting it right. What I've read is to get the neck/shoulder to 750F, but no higher than 800F, so that's what I'm trying to do (but feel free to throw other numbers at me, if that's not what I should be doing). Here are the cases with 750 and 800 Tempilaq applied (750 on the left):

After heating (5 different timings):

Looks like the middle one is what I should use? Am I reading that right?

Side note: it's an induction annealer, so there's no flame to provide a "false indicator" melting on the outside. Tempilaq inside the neck matched the behavior on the outside.

Having never read Tempilaq before, I can't quite tell if I'm getting it right. What I've read is to get the neck/shoulder to 750F, but no higher than 800F, so that's what I'm trying to do (but feel free to throw other numbers at me, if that's not what I should be doing). Here are the cases with 750 and 800 Tempilaq applied (750 on the left):

After heating (5 different timings):

Looks like the middle one is what I should use? Am I reading that right?

Side note: it's an induction annealer, so there's no flame to provide a "false indicator" melting on the outside. Tempilaq inside the neck matched the behavior on the outside.

. If I'm feeling particularly bored one day, maybe I'll test the different heatings and see what effect (if any) they have on group size.

. If I'm feeling particularly bored one day, maybe I'll test the different heatings and see what effect (if any) they have on group size.

Comment