I've got a TM 80% lower I am building up.

I received a stock kit and the tube isn't threading onto the 80% I can get it just started and then it won't thread the rest of the way. I'm leery of putting too much force on it and stripping the 80%.

I can get it just started and then it won't thread the rest of the way. I'm leery of putting too much force on it and stripping the 80%.

This is the second lower I've assembled using a TM 80%.

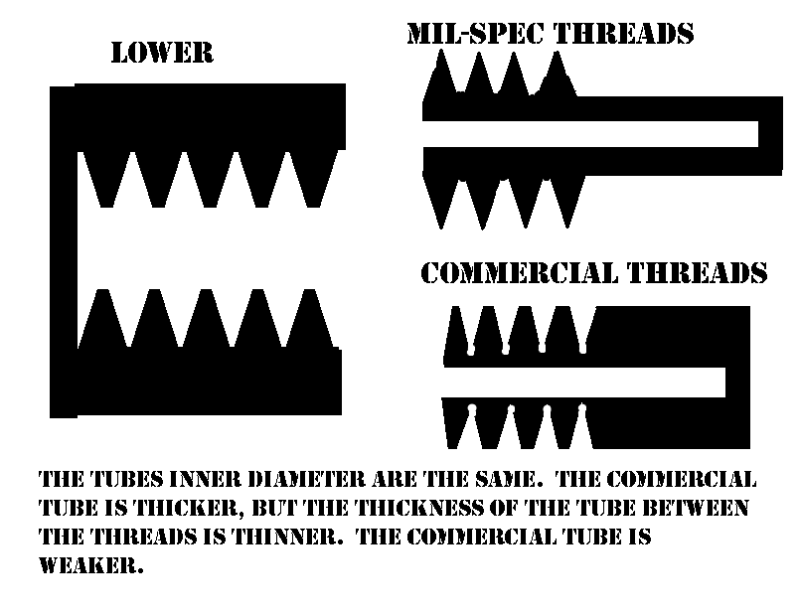

So the question is... are there different threads available for the tubes?

I was so darn close to having one complete rifle and I get this

I received a stock kit and the tube isn't threading onto the 80%

I can get it just started and then it won't thread the rest of the way. I'm leery of putting too much force on it and stripping the 80%.

I can get it just started and then it won't thread the rest of the way. I'm leery of putting too much force on it and stripping the 80%.This is the second lower I've assembled using a TM 80%.

So the question is... are there different threads available for the tubes?

I was so darn close to having one complete rifle and I get this

Comment