I've read all the threads on failures to extract or eject. Does anyone see anything in the linked video that suggests the specific cause?

Unconfigured Ad Widget

Collapse

|

|

|

|

|

|

|

|

Failure to Fully Extract

Collapse

X

-

had a similar problem on my pws pistol upper. pws customer service said if you can move the extractor on the bolt it need a new spring.

i swapped out the extractor spring for http://www.bravocompanyusa.com/searc...spring&Submit=

and i havent had an issue since. -

-

Failures to extract usually involve the extractor...spring...doughnut... crap under extractor also.

Swap it for another complete bolt from a known good AR and re-test.

Over gassed condition can result in light speed bcg movement. Going too fast to pick up the case rim.

Make sure buffer/spring is correct weight/size.

Proper powered ammo. No reloads until you can confirm the pistol works with standard power ammo.

Good luck OP.Last edited by FeuerFrei; 09-14-2015, 12:44 PM.Comment

-

Thanks for the suggestions. It's using a Phase 5 pistol buffer tube and buffer with a David Tubb AR15 Lightweight (300 BLK and Pistol) buffer spring. It's a completely new Daniel Defense chromed BCG. The barrel is a 10.5" AR Stoner 300 BLK. It's got an adjustable gas block currently opened up all the way.

I can see extractor marks on the case rim, but something is clearly not holding for long.Comment

-

For the love of god, why would you think that was a good idea... ୧༼ಠ益ಠ༽୨

Load one round only. Start with gas closed, open one click at a time until it barely locks open. Insert mag with 2 rounds, ensure it feeds the next round. Try with full mag to ensure the whole thing works. Adjust as necessary.Comment

-

I had a bad extractor spring on a brand new BCG. Swapped it - did not use the donut - and back in business. That was after trying & checking gas tube & key, gas port, gas block, lube, blah blah. I could move the extractor with my finger like a loose tooth.10 +1 in the chamberComment

-

^^ This.

In your vid, I can see the bolt retract first without the case (possibly due to the pressure has not dropped enough for the bolt to remove the case from the chamber).

Then the case is pushed out (possibly due to the pressure has dropped enough for the case to shrink in size and what little pressure is left in the barrel ejects the case from the chamber).

I would say try adjusting your gas block first before trying/replacing anything else.

Just my $0.02Comment

-

Thanks again. There were failures to extract starting with two turns of the adjustment screw, so I (not knowing what I was doing) just cranked it up, but I never started with a lower level. I will work up the gas from one click above zero to reliability.Comment

-

It'll be a few weeks before I have an opportunity to test again. I replaced the ejector and extractor springs with some from David Tubb: http://www.davidtubb.com/tubb-spring...ractor-ejector. However, the tension of the previous extractor spring (new DD BCG) seemed fine, and as I mentioned I can see that the extractor marks on the rim show full engagement. The chamber looks good; not mirror polished, but smooth and free from any scratches.

I am guessing that the problem must be over gassing, though don't quite understand the physics involved. I would think that no matter how quickly the bolt retracts, as long as the extractor claw is deep onto the the rim, you should get a good extraction.Comment

-

Not quite, if over gassed, there is more pressure pushing the case against the chamber wall holding the shell in place.

Once the pressure drops, the shell will rebound slightly and there is less force holding the shell against the chamber wall. This is when the case can be extracted, extracting the case sooner will cause problems to either the shell or the extractor all depending on the amount of pressure.

croc4Comment

-

Just to stir the pot a little for the "ejection pattern diagram" haters

10 +1 in the chamber

10 +1 in the chamberComment

-

How the things work is actually simple, but it is involved. If anyone is really curious to understand the parameters behind semi auto or full auto firearm function and theory, go read Vol IV The Machine Gun. You can find the series, for free, at http://www.ibiblio.org/hyperwar/USN/ref/MG/ In particular read the section on blowback actions,then get into the one on gas mechanisms.I am guessing that the problem must be over gassing, though don't quite understand the physics involved. I would think that no matter how quickly the bolt retracts, as long as the extractor claw is deep onto the the rim, you should get a good extraction.

Understand that the case is simply a gas seal. The entire breech mechanism is built to support the case and keep it from bursting. The case is not in any way a load carrying member, if it carries load, it will stretch, it will rupture, it will burst.

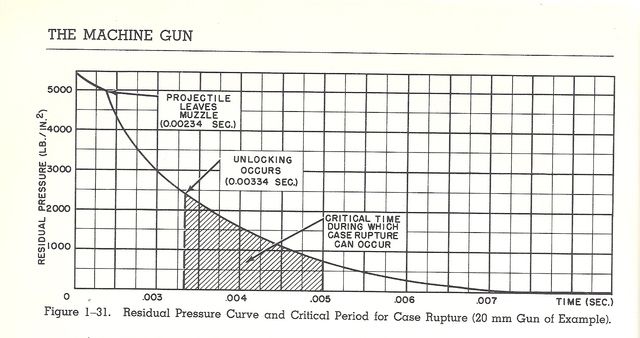

Secondly understand that excessive friction between the case and chamber will defeat any extractor mechanism. That is basically meant by over gassing, the pressures at unlock are so high that the case is stuck to the chamber. Either the extractor pulls off the rim, or it slips off the rim.

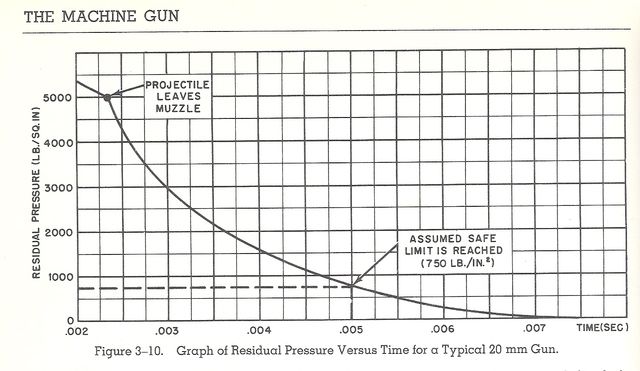

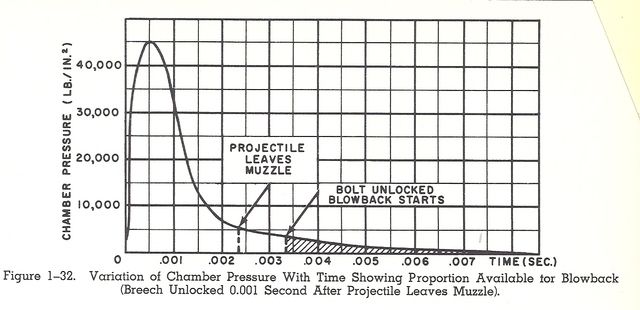

These pressure curves, from AMCP pamphlets, each have an interesting inset. The small curve shows an important pressure curve for a gas gun designer. This is the portion of the curve where the gun unlocks. Gas gun designers have their mechanisms unlock at a time and pressure point when there is still pressure in the barrel. The pressure should be under 650 psia, because a typical case will burst above 650 psia, and the pressure must be low enough that the case is not effectively sticking to the case walls. Given some pressure, but not enough pressure to stick the case in the chamber, what occurs in this time period is a phenomena called the residual blowback effect, where the little pressure in the barrel at unlock helps pop the case out of the chamber like a cork being blown out of a bottle.

These pictures came from Chin, they are representative of the concepts. As you can see, timing and pressure are critically controlled parameters. The action must not open at too high of a pressure or the case will burst.

If pressures at unlock are too high, the case sticks in the chamber. Friction between the case and chamber is always bad, some mechanisms are intolerant of case to chamber friction and required active oiling or greasing of the cases. The Pedersen rifle was one of these, it used passive lubrication in the form of a wax lubricant. Under the temperatures and pressures of combustion the solid wax turned into a liquid and that provided lubrication between the case and chamber. I am considering pre greasing or pre oiling passive lubrication, but this is a term I am making up. Mechanisms that oiled or greased the cases at the time of loading, I consider them active systems, though the differences are probably artificial.

Oilers were very prevalent on a number of pre WW2 machine gun mechanism, Chinn has a whole section on oiler pictures in Vol IV. All of the pre WW2 delayed blowback mechanisms required passive or active case lubrication with greases, oils and waxes, because gas lubrication had not been invented yet. But with the invention of chamber flutes, wax, oil, grease as cartridge lubricants went on the ash heap of history. Chamber flutes provide an active means of gas lubrication. The upper 2/3 rd's of the case is floated off the chamber, the last 1/3 is the gas seal. Chamber flutes are 100% essential in the roller bolt actions, they open up so quickly and early in the pressure curve that without a means of breaking the friction between case and chamber, they won't function.

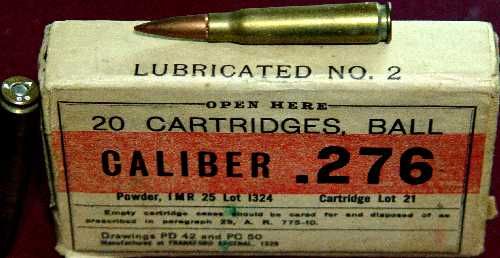

https://en.wikipedia.org/wiki/5.8%C3%9742mm_DBP87 have more taper, a thicker rim, and operate at lower pressures. The Chinese round operates at 41,500 psia : it is always better to do the same job at low pressures than higher pressures. The Chinese case was developed using steel as a case material. Brass is the best case material, but it is expensive. Steel works, is cheaper, but it is stiffer and does not relax as much when pressure drops. So, as can be seen for the 223 and the AR15, because the taper and thickness of the case is not optimum for such a stiff material as steel, steel cased ammunition is more prone to malfunctions.

https://en.wikipedia.org/wiki/5.8%C3%9742mm_DBP87 have more taper, a thicker rim, and operate at lower pressures. The Chinese round operates at 41,500 psia : it is always better to do the same job at low pressures than higher pressures. The Chinese case was developed using steel as a case material. Brass is the best case material, but it is expensive. Steel works, is cheaper, but it is stiffer and does not relax as much when pressure drops. So, as can be seen for the 223 and the AR15, because the taper and thickness of the case is not optimum for such a stiff material as steel, steel cased ammunition is more prone to malfunctions.

Even though the AR15 action does not require chamber flutes to function, because of the limitations of the cartridge, and the high pressures involved, extraction reliability can be improved by the addition of chamber flutes. XTRAN is providing AR15 type barrels with fluted chambers.

I am of the opinion that fluted chambers should be in all gas guns, by breaking the friction between case and chamber you cannot but improve extraction reliability. But whatever improvement is achieved is undoubtedly buried in the extra cost of fluting.

So anyway, for a gas gun to extract reliably, it has to operate within a limited number of parameters. Pressure at unlock is critical, too high of pressure at unlock will result in a failure to extract. Therefore the powder you use is important, slow burning powders will cause malfunctions as the pressure at unlock will be too high. As a general rule, it is better to use faster powders than slower in these mechanisms. Of course, too much powder will result in too high a pressure at unlock. Timing is of course critical, if the bolt is accelerated too quickly, too soon, pressures at unlock will be too high. Therefore with mechanisms with adjustable gas mechanisms, too much gas will result in failures to extract.

What I wrote is probably too long and boring, but this is an involved subject. For those who want a real understanding of the principles of how these things work, go read Chin Vol IV. Then go look at Vol 1 for all the pretty pictures of the historical machine guns.Last edited by slamfire1; 09-17-2015, 12:44 PM.Comment

Calguns.net Statistics

Collapse

Topics: 1,857,970

Posts: 25,038,762

Members: 354,530

Active Members: 6,023

Welcome to our newest member, Boocatini.

What's Going On

Collapse

There are currently 5301 users online. 22 members and 5279 guests.

Most users ever online was 65,177 at 8:20 PM on 09-21-2024.

Comment